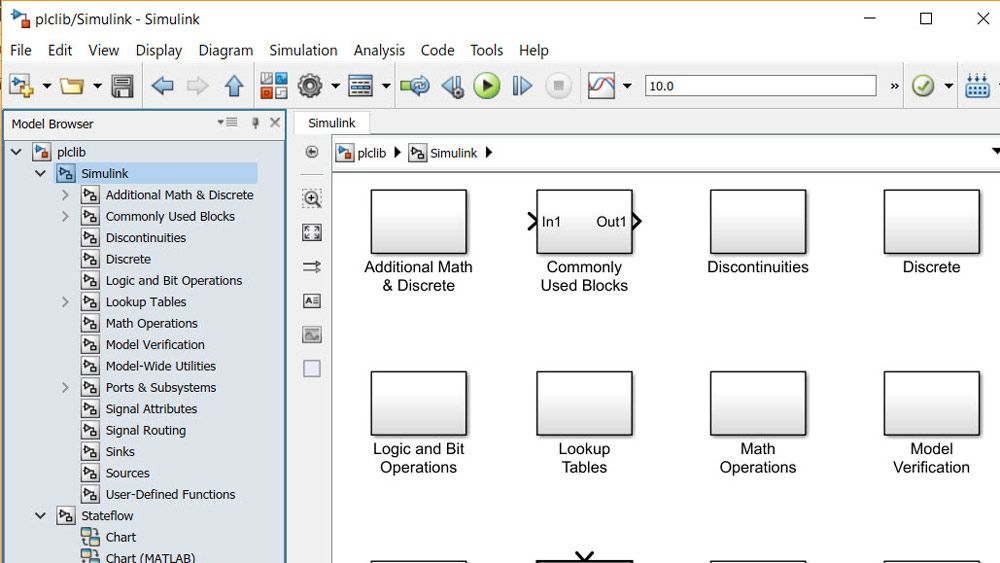

Simulink PLC Coder generates hardware-independent IEC 61131-3 Structured Text and Ladder Diagrams from Simulink models, Stateflow charts, and MATLAB functions. Structured Text is generated in PLCopen XML and other file formats supported by widely used integrated development environments (IDEs), including 3S-Smart Software Solutions CODESYS®, Rockwell Automation Studio 5000, Siemens TIA Portal, and Omron® Sysmac® Studio. Ladder diagrams are generated in file formats supported by Rockwell Automation Studio 5000. As a result, you can compile and deploy your application to numerous programmable logic controller (PLC) and programmable automation controller (PAC) devices.

Simulink PLC Coder generates test benches that help you verify the Structured Text and Ladder Diagrams using PLC and PAC IDEs and simulation tools. It also provides code generation reports with static code metrics and bidirectional traceability between model and code. Support for industry standards is available through IEC Certification Kit (for IEC 61508 and IEC 61511).

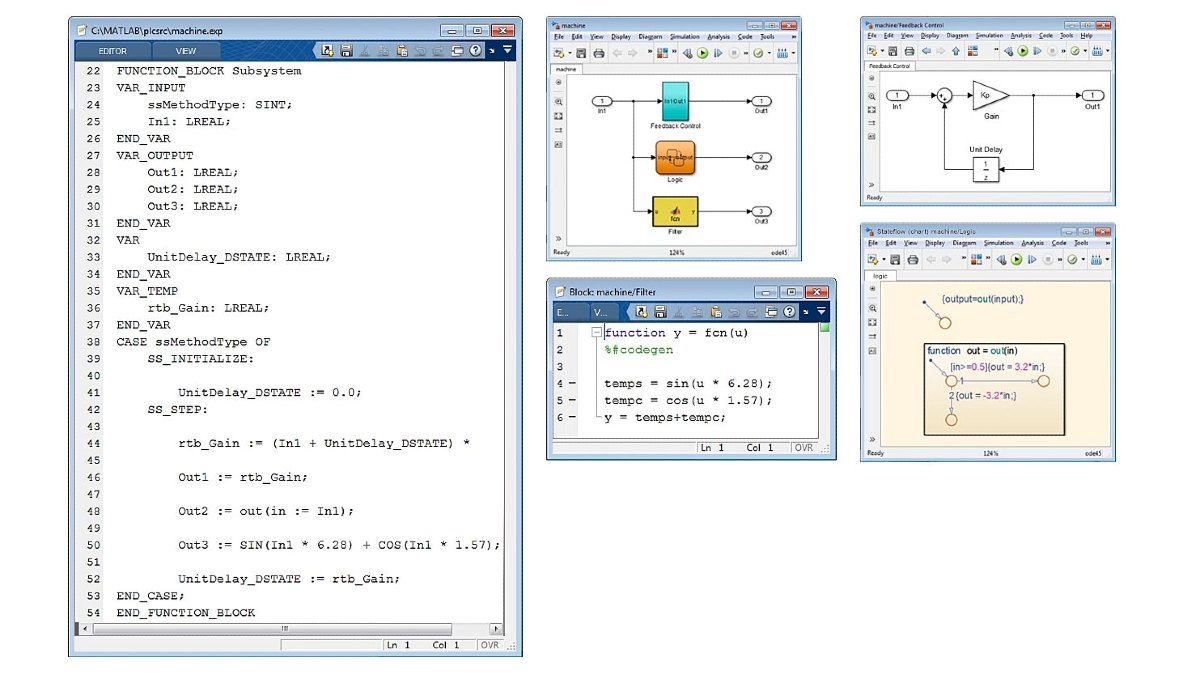

Generate Structured Text

Generate hardware-independent IEC 61131-3 Structured Text from your Simulink models containing blocks, Stateflow charts, and MATLAB code.

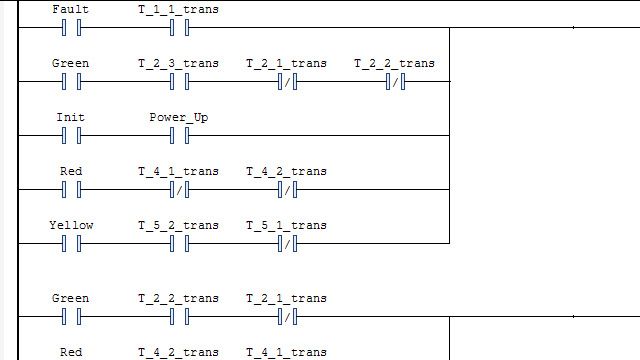

Import and Generate Ladder Diagrams

Import Rockwell Automation® Studio 5000 Ladder Diagrams into Simulink for simulation and verification. Generate Ladder Diagrams from Simulink models for Studio 5000.

Support for Third-Party IDEs

Generate Structured Text in file formats used by third-party IDEs, including Siemens® STEP 7/TIA Portal, Rockwell Automation Studio 5000, Mitsubishi Electric MELSOFT GX Works3, 3S CODESYS®, and PLCopen XML.

Code Optimization

Apply optimizations that reduce memory size and increase execution speed of the generated Structured Text and Ladder Diagrams for your hardware and IDE.

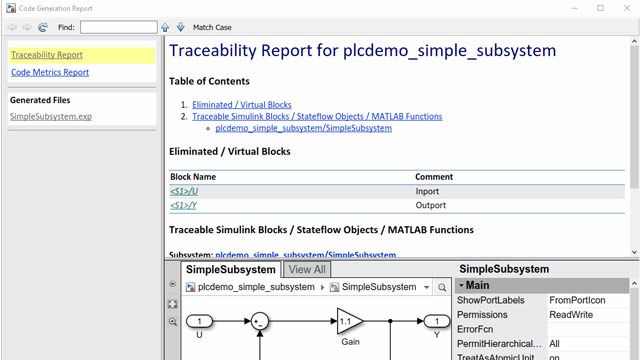

Commenting, Bidirectional Tracing, and Documenting Code

Add comments and bidirectionally trace model components to generated code for debugging and code reviews.

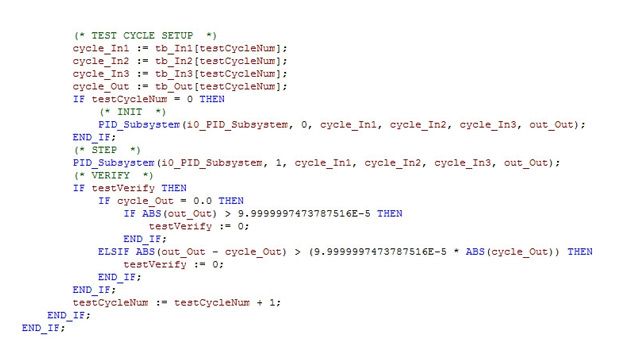

Code Test and Verification

Generate a test bench to verify Simulink simulation results match results in PLC within an acceptable tolerance.

Product Resources:

“Using Model-Based Design, we were able to immediately implement model predictive control into the PLC through automatic code generation.”

Yusuke Sugiuchi, Shibaura Mechatronics Corporation